COMMITMENT TO THE ENVIRONMENT

Environmental Policy

Murakami Corporation strives for human and Earth friendly monozukuri and to serve people through all its corporate endeavors.

1. Environmental Regulation Compliance and Pollution Prevention

We follow all environmental laws and regulations and undergo proactive preventative measures regarding environmental pollution.

2. Environmentally-aware Product Development and Production

From the very start of product development, we keep environmental impact and recycling in mind and maintain strict management throughout the production process.

3. Regional Coexistence

We build bonds with local communities through environmental maintenance and protection efforts.

4. Carbon Neutral Initiatives

The entire Murakami group works in unison towards achieving carbon neutrality.

Taro Murakami, President/CEO

ISO14001 Certification

In January 2001, to commemorate our move into the 21st century, we launched our Environmental Management System, which continues to guide our efforts towards environmentally-friendly operation. By December 2001, all domestic offices and affiliate companies had achieved ISO14001 certification.

ISO Certified Offices and Affiliate Companies

Domestic offices and six affiliate companies

- Head office

- Fujieda factory

- Oigawa factory

- Tsukiji factory

- Eiji Corporation

- Murakami Kasei Corporation

- Murakami Business Service Corporation

- Murakami Kyushu Corporation

- Murakami Express Corporation

- Murakami East Japan Corporation

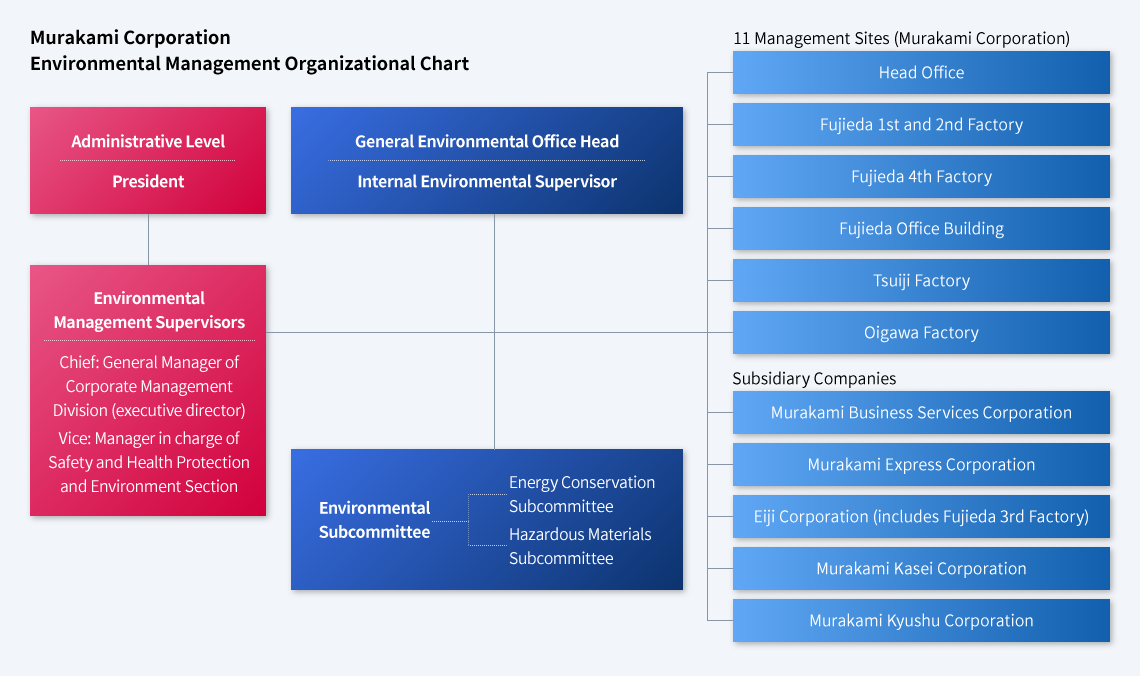

Environmental Management Organizational Structure

We take an organizational approach to defining objectives and conducting environmental management, which is structured as outlined below.

Environmental Information

- 1. Environmental InstallationsRooftop greening / Solar power

- 2. CO2EmissionsCO2 emissions record

- 3. Waste DisposalAmount of waste generated

- 4. Regional ActivitiesPublic beautification / Flower planters

- 5. Waste ReductionReduction of waste generated from paints, plastics, glass, etc.

- 6. Environmental Product DevelopmentDevelopment, sales and introduction of environmentally friendly products

1. Environmental Installations

Introduction of Environmentally-aware Installations

The Tsukiji factory was designed to be a state-of-the-art base of production. The wide amount of space available was utilized towards new installations such as rooftop greening, solar power generators, and LED lighting.

Solar Power System

480 monocrystalline solar panels, generating a maximum of 100kW, have been installed on the roof as part of proactive efforts to increase green, renewable sources of energy.

Rooftop Greening

2000㎡ of rooftop space have been covered with Mexican stonecrop, which helps reduce the temperature inside the factory during summertime. This reduces electricity consumption and creates a pleasant working environment.Expansion of Solar Power System

Expansion of Solar Panels at Tsukiji Factory

Originally, 480 monocrystalline solar panels were installed to reduce CO2 emissions and shift towards green renewable energy sources. In February 2022, work began to utilize more factory space and increase this by 1,936 panels that altogether will generate a maximum of 836kW. Yearly output will reach around 818MWh, covert 10.8% of the factory’s energy consumption to renewable sources, and reduce CO2 emissions by around 355 tons per year. Future endeavors to further expand renewable energy and aid the environment are always underway.

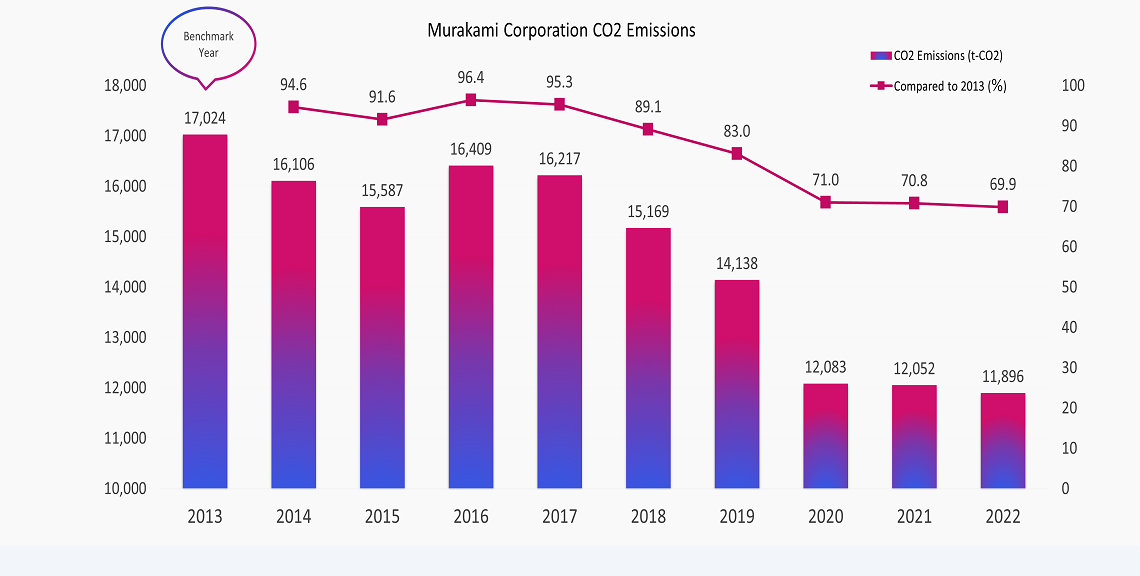

2. CO2 Emissions

Our CO2 Emissions Record

CO2 reductions efforts and energy efficiency begin with an understanding of our current CO2 emissions. With 2013 levels as a benchmark, we set medium-term objectives for CO2 reduction.

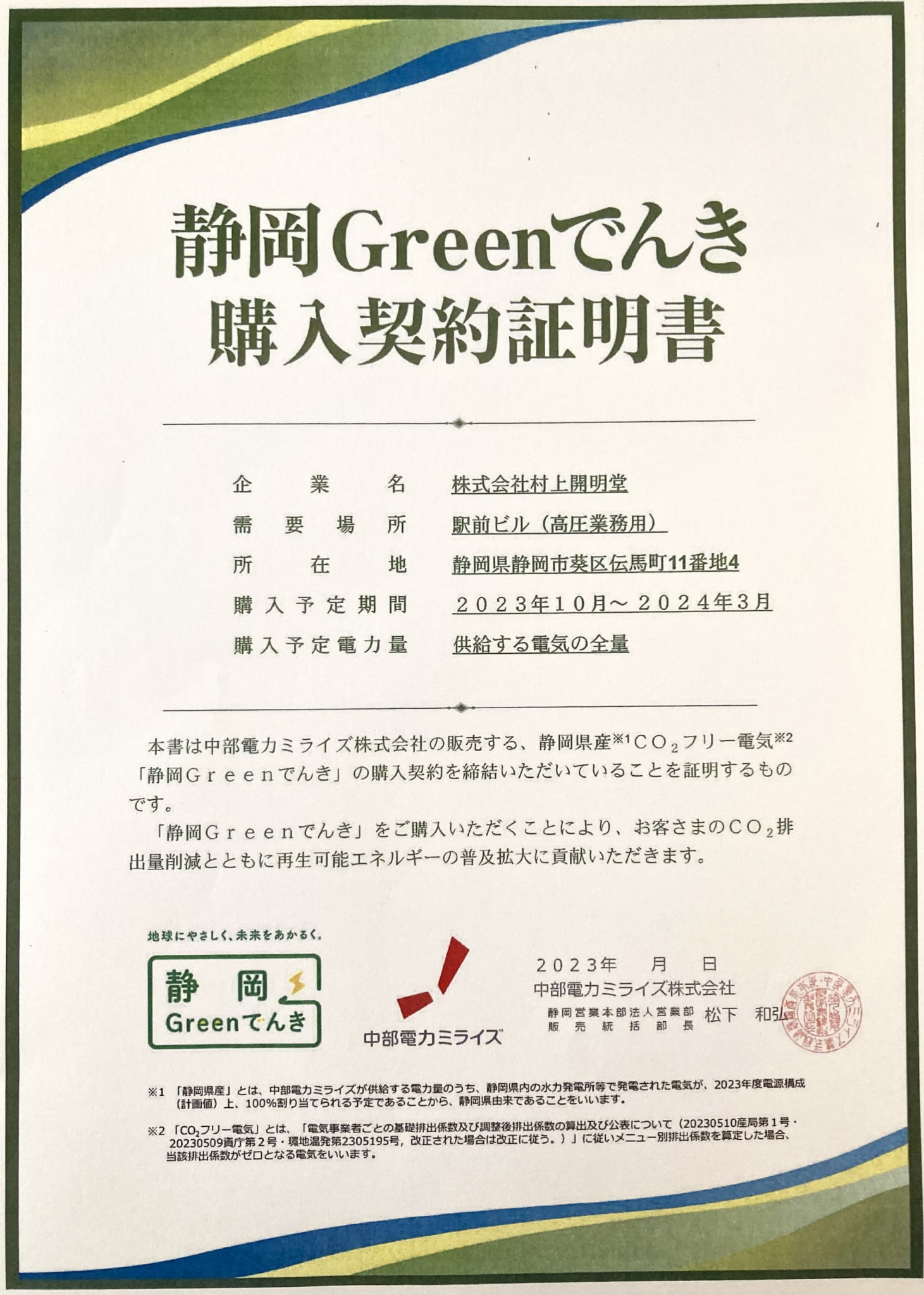

CO2-Free electricity introduced at our Shizuoka Headquarters in Japan

We have introduced "Shizuoka Green Electricity" effective October 1, 2023.

As a result, all electricity used at our Headquarters will be 100% renewable energy, and CO2 emissions associated with electricity use will be virtually zero.

As a result, all electricity used at our Headquarters will be 100% renewable energy, and CO2 emissions associated with electricity use will be virtually zero.

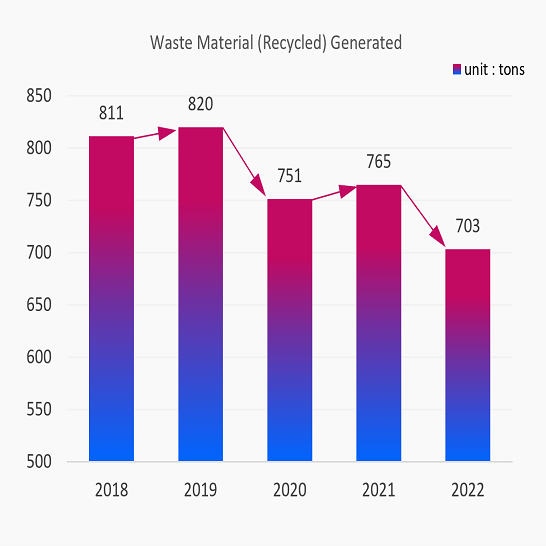

3. Waste Disposal

Waste management regulations have been set to guide management and reduction of waste activities to ensure any waste products discharged in the course of operations are properly handled in accordance with Waste Management Law.

- Amount of Waste Generated

703 t/year *2022 91.9% YoY (8.1% decrease) - Discharge of Valuable Resources

1724 t/year *2022 99.0% YoY (1.0% decrease) - Landfill Disposal

0 t/year 100% resource circulation

Waste Generated Yearly Trend

| 2013-2015 | reduction |

|---|---|

| 2016-2017 | large increase |

| 2018-2019 | increase |

| 2019-2020 | large reduction |

| 2021 | increase |

| 2022 | large reduction |

4. Regional Activities

A key policy of Murakami Corporation is “Regional Coexistence,” which drives efforts to benefit local environments. Every factory serves as a base for public beautification efforts.

Regional Coexistence Public Beautification

Community Outreach Flower Planters

Community outreach includes the distribution of flower planters as part of our corporate role to serve as a beneficial presence in society. Planters are replaced three times a year with seasonal blossoms.

5. Waste Reduction

Reduction of Paint and Thinner Waste

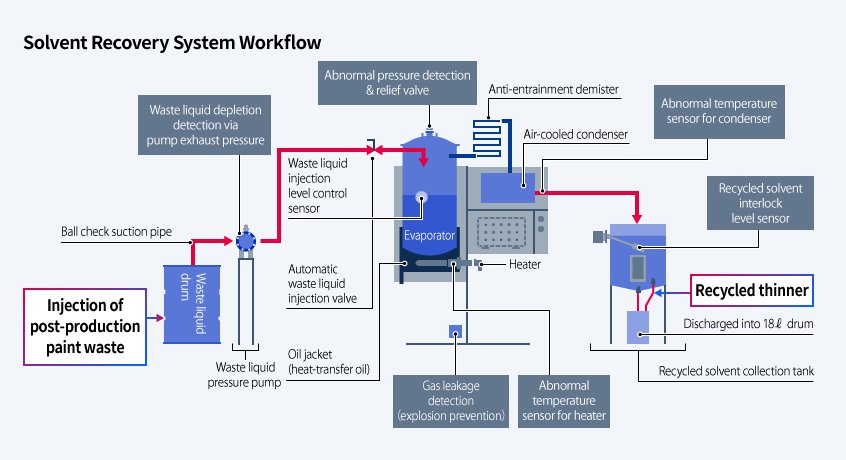

Painting Process

Adoption of Solvent Recovery Apparatus for Thinner RecyclingLiquid paint waste (paint waste, thinner waste) is distilled in-house and

- Solvent Recovery Apparatus

90% of thinner is recoverable from paint waste, which also reduces purchases of cleaning thinner

Reduction of Plastic Waste

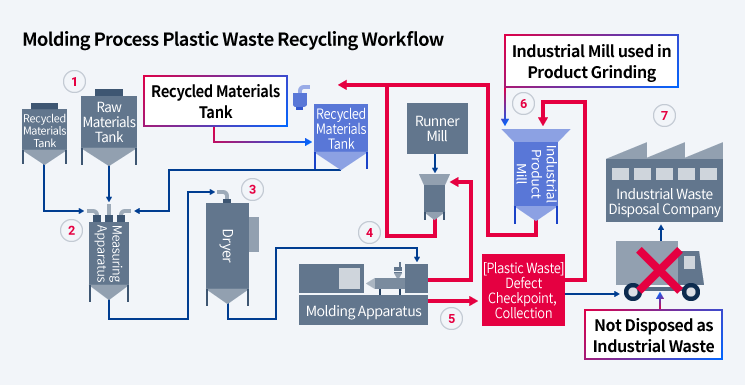

Molding ProcessPlastic waste (runner, checkpoints, defective product) is ground up and .

- Raw (virgin) and recycled (resin pellets) materials are injected into tanks or automatically collected in the ground material (runner mill) tank.

- Virgin, recycled and ground material are sent from the raw materials tank to the measuring apparatus.

- Raw materials are mixed in the measuring apparatus and sent to the dryer.

- The dryer serves as a centralized supply for the molding apparatus.

- Throwaway product made during setting, intermittent die maintenance, or momentary stops is recovered by the operator for recycling.

- Recovered plastic waste is ground in the industrial product mill and automatically recycled.

- This material is not sent out for disposal.

Reduction of Glass Waste

Mirror Process

Development of glass waste recycling business:Foam glass manufacturing, commodification

Development of glass waste recycling business:Foam glass manufacturing, commodification

Creation of Products from Glass Waste

A great benefit to the environment

| Recycled glass | foam glass |

|---|---|

| Function | Deodorizer, water purification, weed control, etc. |

| Results |

|

6. Environmental Product Development

Heated Washer

- Front window frost removal is often a time-intensive process with only temporary results. A heated washer solves this issue in a safe and easy way, greatly reducing worktime involved.

- A user-friendly tool that helps reduce use of heaters in removal of window frost, which in turn saves energy and reduces CO2 emissions.