OPT-ELECTRONICS

Multi-purpose high-precision, high-quality optical coating technology

Murakami Corporation rearview mirrors technology have enhanced transparency, reflectivity and polarization thanks to the development of high-precision, high-quality optical coating technology used in applying muti-layered thin film over glass and resin.

Production technology we have built up over our long history in the automobile industry combined with high standards for QCD allow us to fulfill a diverse array of customer needs.

Production technology we have built up over our long history in the automobile industry combined with high standards for QCD allow us to fulfill a diverse array of customer needs.

INDEX

Optical Coatings to Reduce Variation against Angle of Incidence

LiDAR and Highly Reflective Mirrors for Wide Angles of Incidence

Opt-electronics Technology in the Home and Office

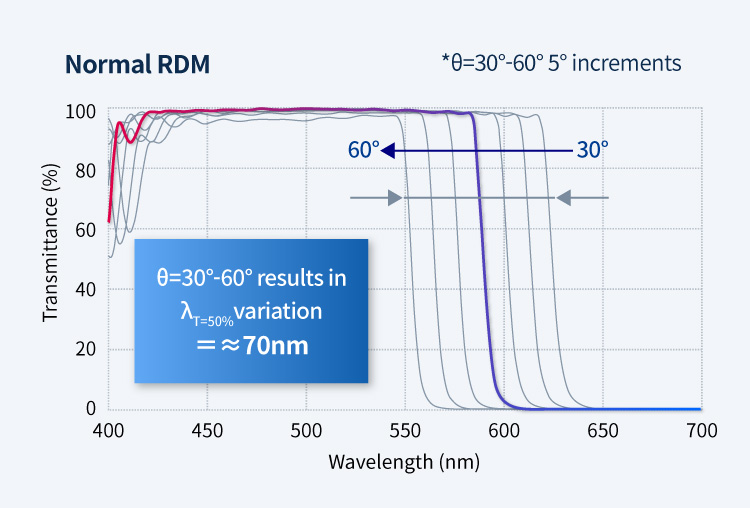

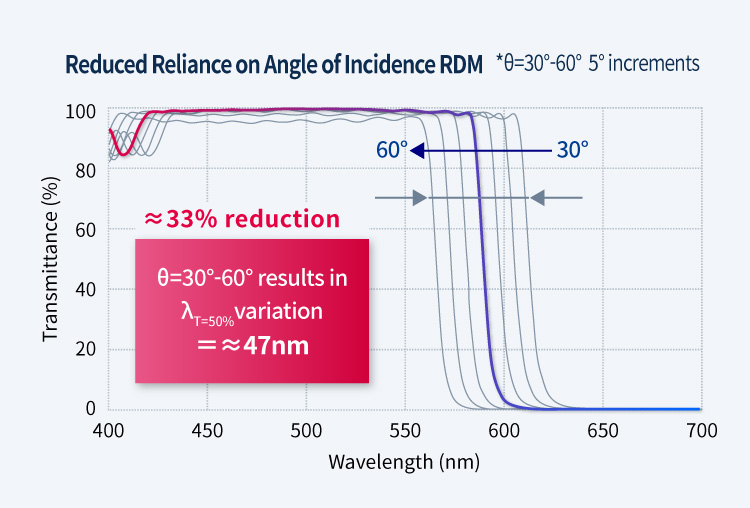

Optical Coatings to Reduce Variation against Angle of Incidence

In optical path design concerning optical devices, you a rarely working with a nice, level beam of light from start to finish. Instead, the angle of incidence θ most often varies as the light passes through filters or reflects off mirrors. In general, with dielectric multi-layer mirrors, the θ value affects optical characteristics, which means the nature of the light varies depending on the angle of incidence.

To combat this, we have developed multilayered coatings that minimize changes in optical characteristics that would normally occur with change to the angle θ, making the source and angle of the incoming light have less impact on the reflected image.

To combat this, we have developed multilayered coatings that minimize changes in optical characteristics that would normally occur with change to the angle θ, making the source and angle of the incoming light have less impact on the reflected image.

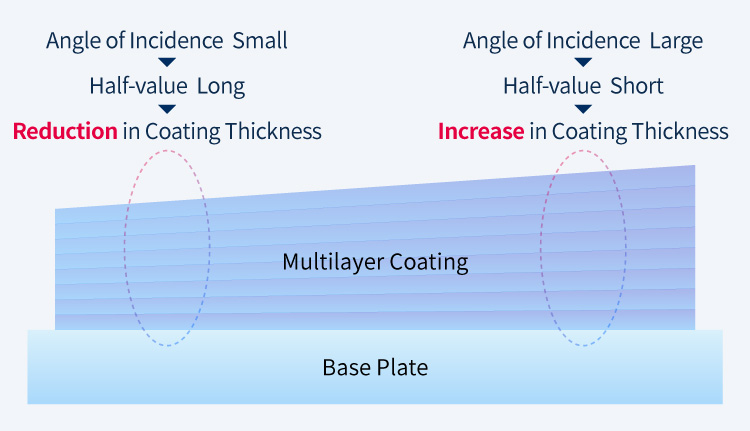

Wedge Gradient Deposition

As stated above, changes to the angle of incidence θ affect the optical characteristics of light. Another way to combat this is to add wedge gradients, which makes the coating thicker in certain areas for the purpose of adjusting the light’s properties. A dichroic mirror (filter) with a T=50% wavelength (half value) is proportional to the full coating thickness, so adjusting the coating thickness is one method to compensate for wavelength halving caused by changes in the angle θ.

Murakami Corporation jig design technology allows for the high precision adjustment of coating thickness.

Murakami Corporation jig design technology allows for the high precision adjustment of coating thickness.

Examples of Wedge Coating

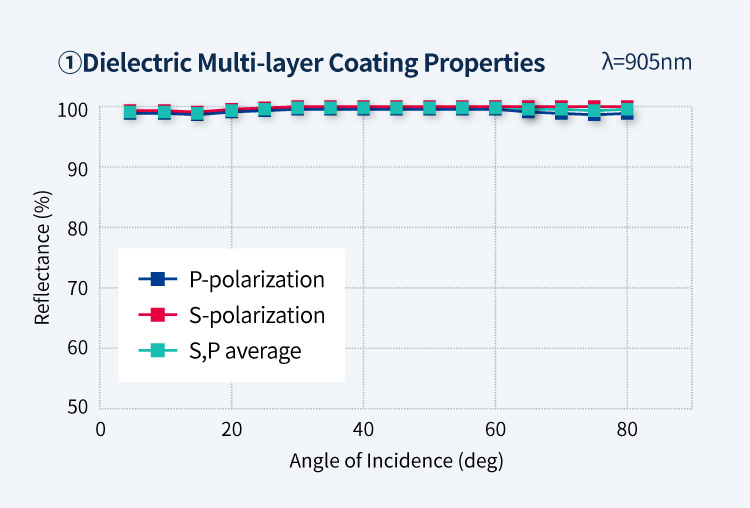

LiDAR and Highly Reflective Mirrors for Wide Angles of Incidence

Recently, LiDAR (Light Detection and Ranging) has garnered much attention for its use in automobile sensors.

Accurate detection of obstacles at wider angles and farther distances requires mirrors with high reflectivity across a greater angle of incidence.

Murakami Corporation propose two main applications regarding functionality and cost.

Accurate detection of obstacles at wider angles and farther distances requires mirrors with high reflectivity across a greater angle of incidence.

Murakami Corporation propose two main applications regarding functionality and cost.

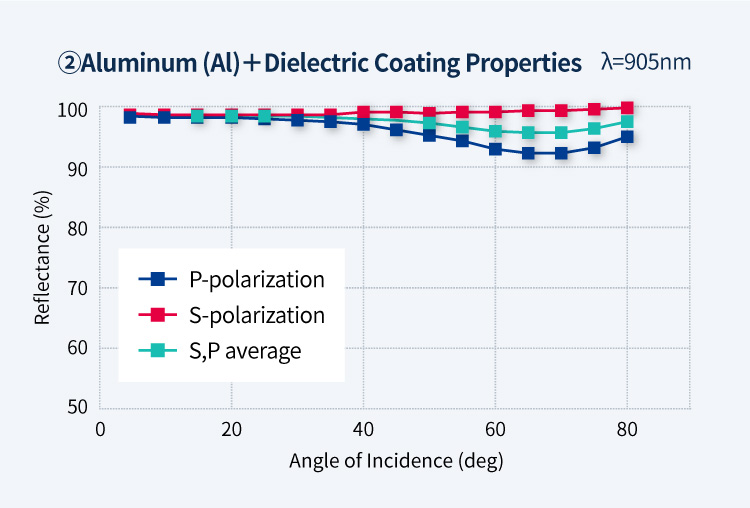

- Functionality: Dielectric Multi-layer Coating

- Cost: Aluminum (Al)+Dielectric Coating

Opt-electronics Technology in the Home and Office

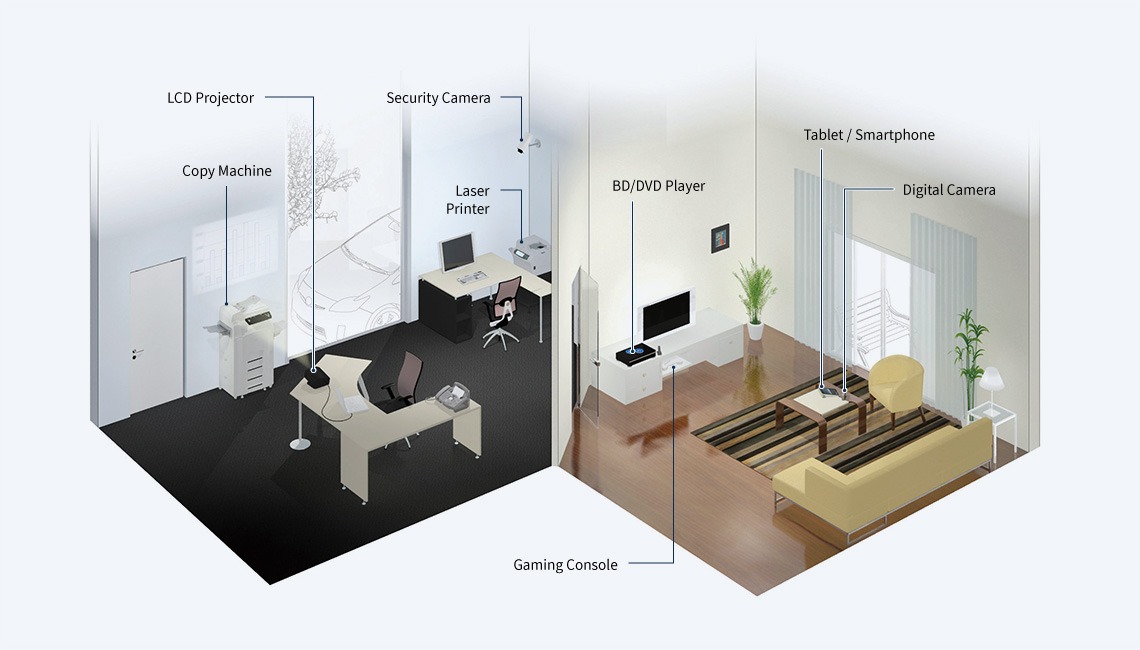

Imaging Devices

A wide variety of optical filters are used to power devices such as digital cameras, LCD projectors, HD-capable TV cameras, and more. Specialized parts can be made in bulk or as single units.OA Devices

Optical filters are also a necessity part of OA devices, including workplace laser printers, scanners and photocopiers. Our optical coating technology is used in devices where high-fidelity is essential.

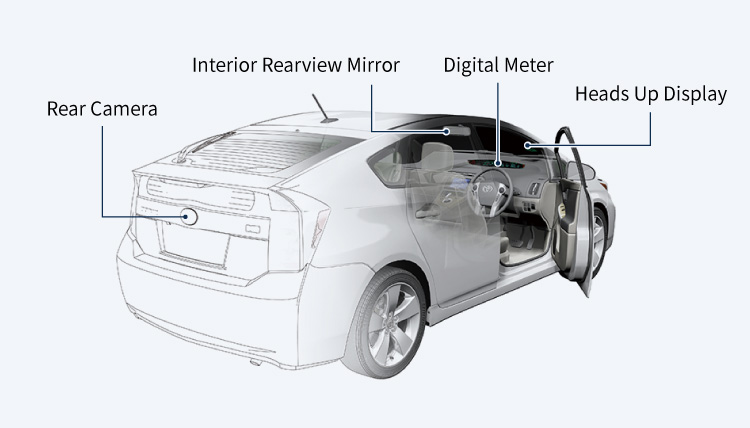

Vehicle-mounted Devices

Information from the windshield odometer feeds into a heads-up display. Camera units that fold into the dashboard utilize our optical coating technology and products.

Optical Coating Manufacturing Process

The integrated manufacturing system ensures quality and efficiency from cutting of the base materials to molding of the final product.

STEP01

Plate Fabrication

Glass plates are cut from original material.

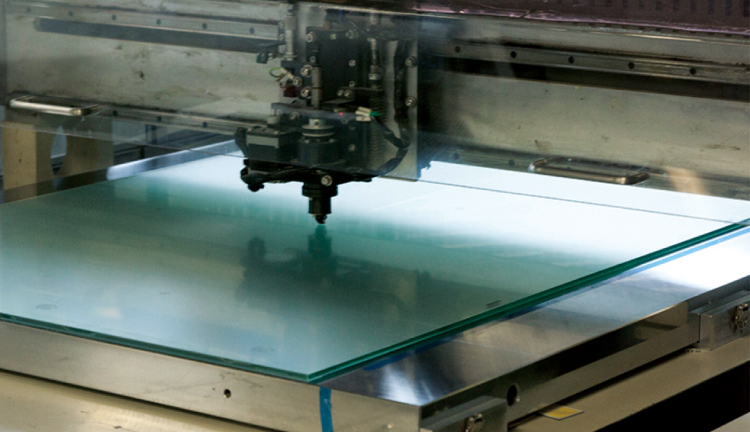

Cutting

An NC machine using scribing to fashion the glass into the proper size for the product.

Bending

The glass plate is heated until malleable and shaped using to the mold using gravity and suction.STEP02

Cleansing

Particulate matter is removed from the surface to ensure smoothness.

Chamfering

The glass is treated via an autonomous process which bevels the edge followed by a polishing and washing.

Ultrasonic Cleansing

Contamination is removed from the surface using ultrasonic vibrations.STEP03

Thin-film Deposition

Machines with nanometer level precision add layers of film to the surface to achieve desired functionality.

Batch Vapor Deposition Machine

Utilizes a vacuum chamber to add dozens of thin film layers to a surface, making possible the production of large lots.

Inline Deposition Machine

Specializes in multi-layer deposition involving fewer layers.Evaluation & Analysis

Products uses optical coatings are evaluated regarding a variety of criteria.

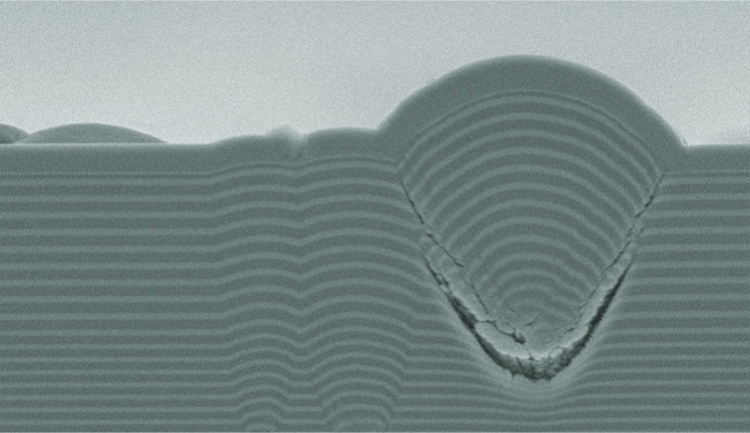

Scanning Electron Microscope (SEM)

A finely focused beam of electrons causes atoms on the material to release secondary electrons, which are used to map the surface. An energy dispersive spectrometer (EDS) used in conjunction can then image the distribution of elements on the surface.

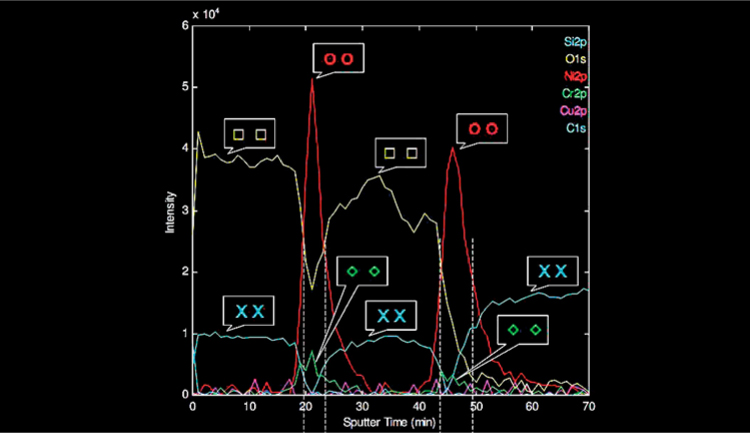

X-ray Photoelectron Spectrometer (XPS)

Uses X-rays to measure photoelectron energy distribution and analyze the elements and chemical bonds on the outermost surface.

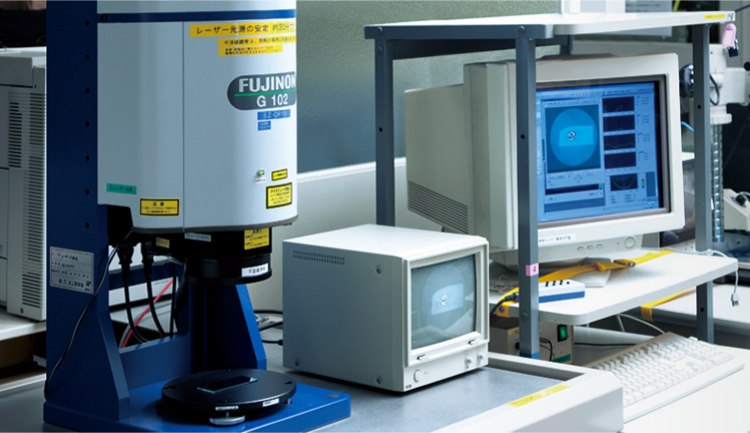

Laser Interferometer

Uses a precise laser to scan the product surface with the resulting data checked for any irregularities.

Other Analysis

- Spectrophotometer

- X-ray Fluorescence Spectrometer

- Optical Microscopes

- Temperature and Humidity Control / Temperature and Shock Resistance / Misc. Testing Equipment (Salt Sprayer, etc.)