Lighting the way for the security of seeing 140-year history

Became a specialized manufacturer of rear-view mirrors

*Honorifics Omitted

1958

CompanyStarted on production of rear-view mirrors for automobiles

After consulting with Toyota Motor Corporation, who were worried about defects in rear-view mirrors delivered by other companies, our company started prototyping and producing rear-view mirrors for automobiles. After much trial and error, we developed our own “triple molding furnace” and turntable type production system, preparing for the subsequent increase in demand in the age of motorization.

1958

ProductDeveloped glue mirror (purple-blue mirror)

After in-house research, we developed our own “purple-blue plating method”. Glue mirrors with high visibility and a sense of luxury were used for the Toyota Crown, Corona, Publica, etc.

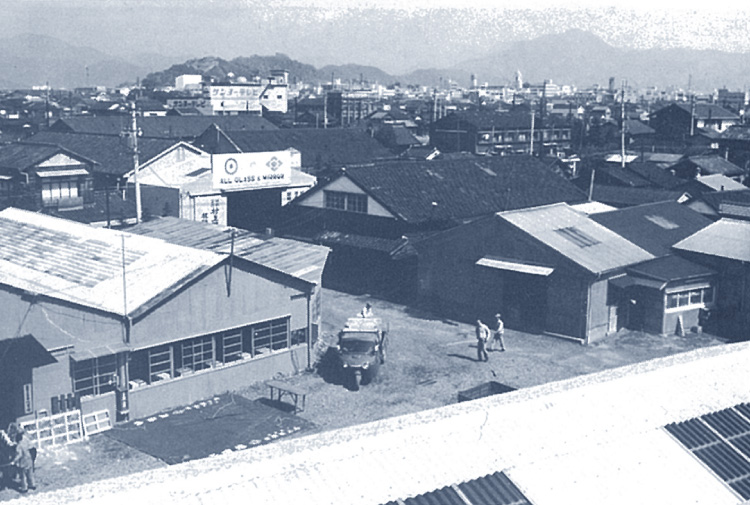

1961

CompanyBecame a manufacturer of finished rear-view mirrors

Our production facilities, which had been gradually expanded until now, were consolidated at the Miyamotocho Factory, thereby establishing a specialized factory for integrated production. Soon after, we added the long-awaited metal processing technology, and the company embarked on a new path as a manufacturer of finished rear-view mirrors.

1963

CompanyCompleted the Kaimeido Building

We completed the five-story “Glass Palace” in Shichikencho. It has become a landmark of Shichikencho-dori Avenue with its modern appearance that makes extensive use of glass.

1963

ProductAluminum frames

With the increasing number of Western-style modern houses, aluminum frames have been chosen for their aesthetic design and functionality.

1967

CompanyOpened our Fujieda Office

We opened our Fujieda Plant in Fujieda City, Shizuoka Prefecture to expand production of rear-view mirrors.

CompanyStarted business with Mitsubishi Heavy Industries, Ltd. (now Mitsubishi Motors Corporation)

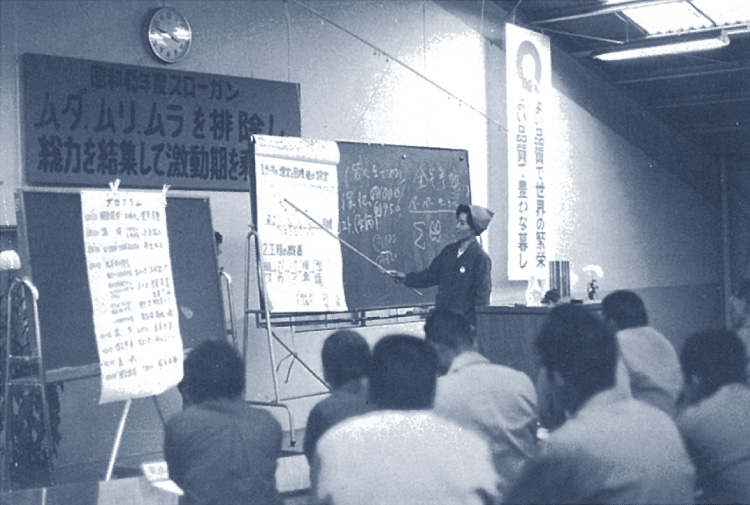

CompanyLaunched QC activities

Learning from Toyota Motor Corporation, the pioneer of TQC (Total Quality Control), our Engineering Section in our Manufacturing Division played a central role in developing QC activities. It became the foundation of our quality control that continues today.

1968

CompanyOpened our Tokyo Office

We established our Tokyo Office as a base for the building materials business in the Tokyo metropolitan area.1968

ProductFender mirror for Toyota 2000 GT

ProductPlastic bullet-shaped wired shockless mirror

Used for the Toyota Corolla. Our unique design was well received.

1969

CompanyHere is central Honshu

In August 1969, we installed a large neon sign on the roof of our Miyamotocho head office.

1970

CompanyIntroduced divisional system

We introduced a divisional system, with the Glass Division (Head Office) and the Rear-view Mirror Division (Fujieda).1972

ProductWired remote control fender mirror

Used for the Toyota Celica and Carina.

1976

CompanyStarted business with Honda Motor Co., Ltd.

1977

CompanyOpened our distribution center office (Shizuoka City)

Opened our distribution center office (Shizuoka City) as a base for the building materials business.1979

CompanyStarted business with Nissan Motor Co., Ltd.

1979

ProductSputter chrome surface mirror (first in the world)

1982

CompanyStarted business with Suzuki Motor Co., Ltd. (now Suzuki Motor Corporation)

1982

ProductMass production type W-hinge type door mirror (first in Japan)

1986

ProductElectric retractable door mirror switch controller (first in Japan)

1988

ProductElectrochromic mirror